automatic shrink wrapper delivers a compelling return on investment, making it indispensable ideal process equipment for cost-conscious printing and packaging industries.

|

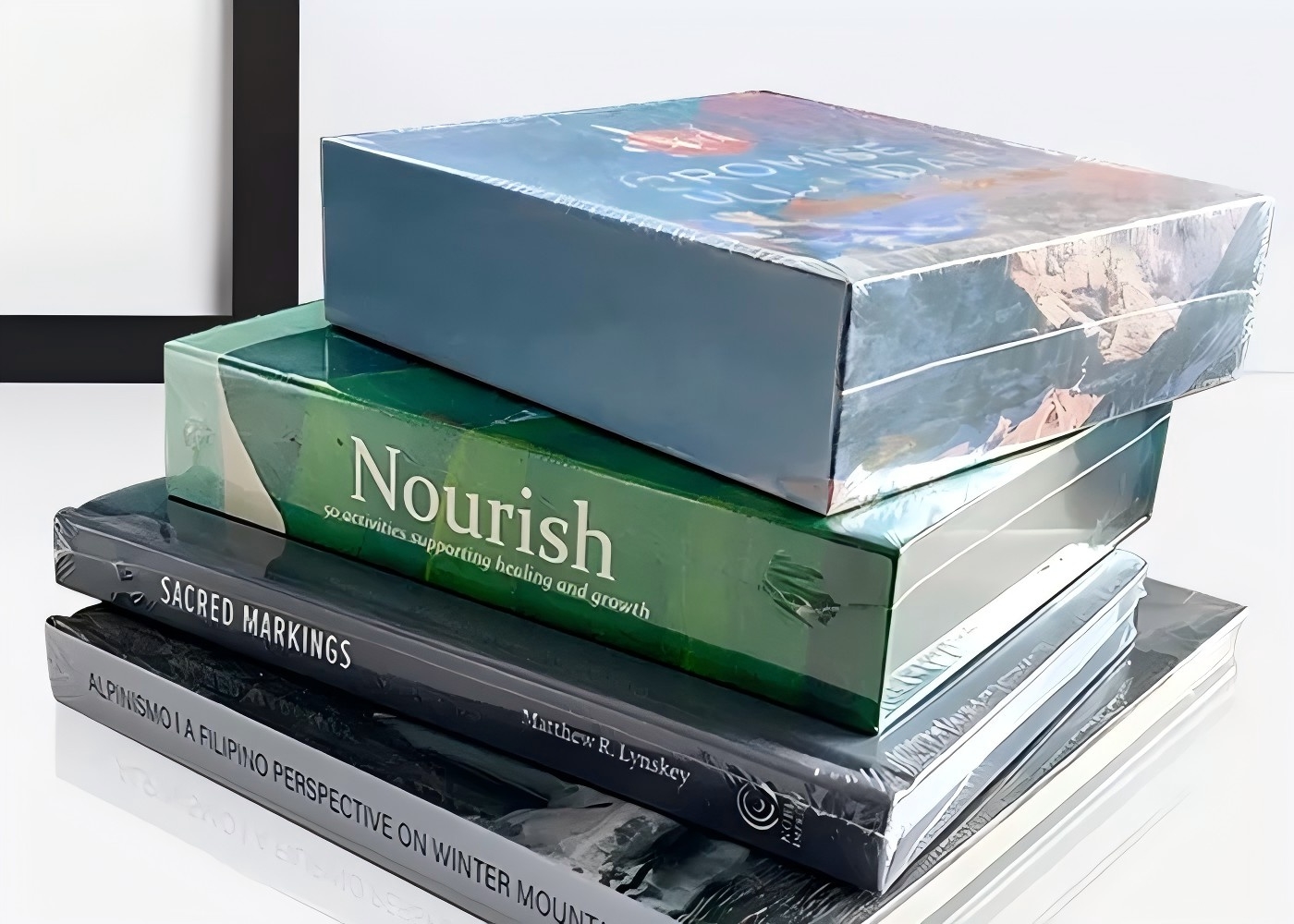

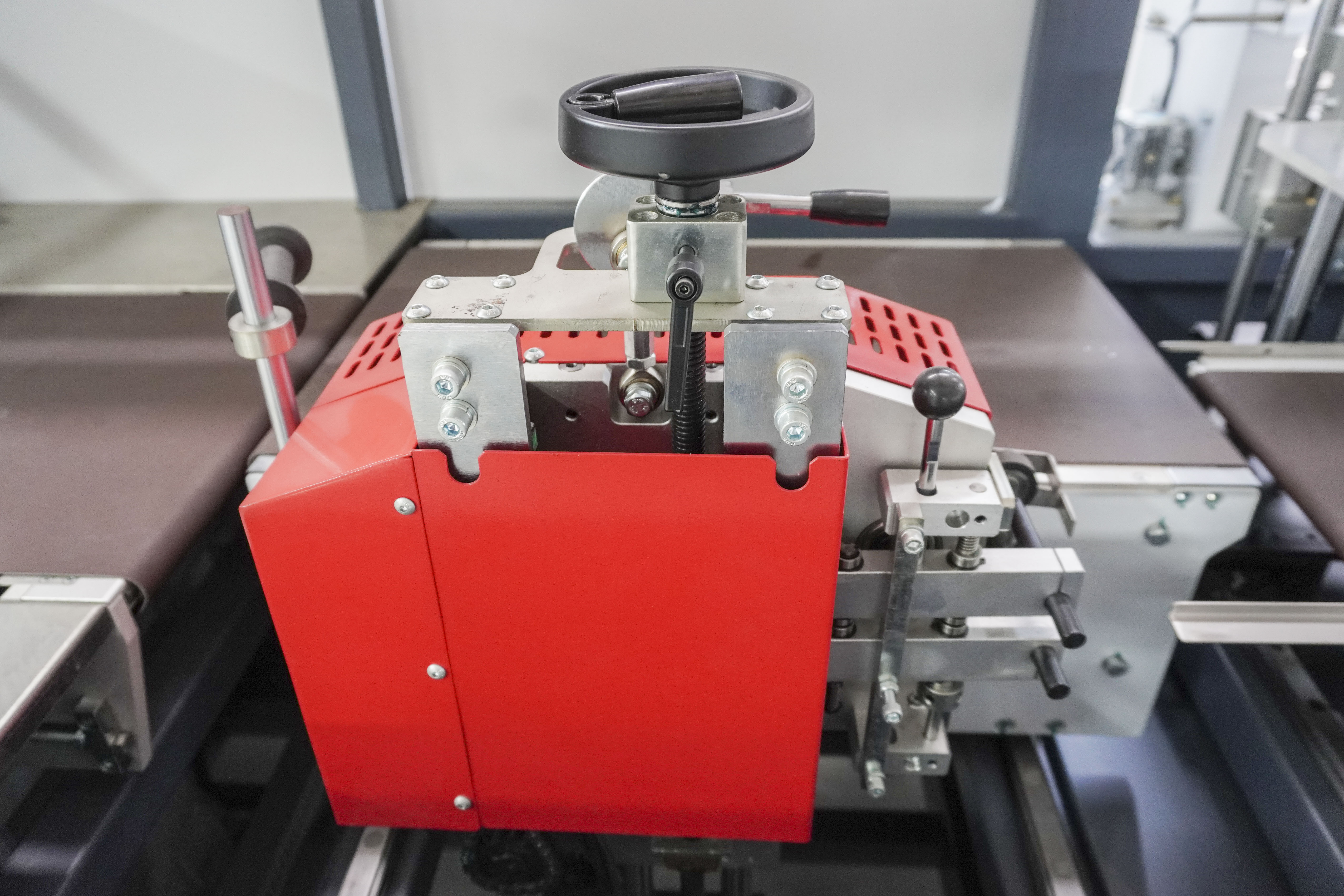

In the demanding environment of book binding and finishing, optimizing the packaging stage is crucial for profitability and competitiveness. Manual bagging and hand wrapping are slow, labor-intensive, and prone to inconsistency. The solution lies in automatic shrink wrap machines specifically engineered for packaging books & binding. This high-speed book shrink wrapping machine delivers unparalleled high efficiency and low cost, processing up to 80 pieces per minute while significantly saving labor. It's the definitive answer for publishers and binders handling hardcover books, paperbacks, spiral bound notebooks, wire bound journals, glued bound diaries, and notepads seeking to enhance throughput and reduce operational expenses. The efficiency starts with seamless integration. Comprising an automatic book loading unit, automatic sealing and cutting unit, heat circulating shrink stove, and automatic book unloading units, this book packaging equipment forms a continuous, automated production line. A key feature enhancing flexibility is that these four units can be separately moved according to the layout of the site. This modularity allows for optimal floor plan adaptation in existing packaging and distribution facilities or warehouses. The automatic loading/unloading conveyors ensure smooth product flow without manual intervention between stages, maximizing uptime.  Precision automation drives speed and reduces waste. The automatic film feeding is intelligently controlled. Electric eyes (sensors) operating in horizontal and vertical groups, combined with timing devices, automatically adjust the cutting size to match each book or notebook fed from the automatic book feeding table. This ensures minimal film usage and eliminates errors. The cutting mechanism itself – a Teflon coated constant temperature blade – operates at 1m/sec, enabling high speed cutting with good effect. The Teflon coating is essential for no adhesion, preventing film jams and ensuring continuous sealing with zero consumption (minimal waste) and zero pollution.  The heat shrinking part is designed for both effectiveness and economy. The thermal cycle contraction tunnel employs integrated heat controlling and allows for freely adjusted wind direction, ensuring rapid and uniform shrinkage even for challenging items like spiral bound or hardback type of book products. Double layer insulation curtains significantly contribute to energy saving by retaining heat within the tunnel, reducing power consumption while maintaining the constant temperature needed for perfect results. This efficient design minimizes operational costs associated with the shrinking process.  Beyond speed and efficiency, reliability underpins the low cost of ownership. The electronic control part utilizes components from well-known international brands like Panasonic, Omron, and IFM, guaranteeing equipment operation stability and a low failure rate. Critical functions like the horizontal knife are powered by a responsive servo motor drive, ensuring precise, repeatable movements crucial for high-speed operation. By reducing labor costs, minimizing material waste (zero consumption), lowering energy usage (energy saving), and preventing costly downtime through stability, this automatic shrink wrapper delivers a compelling return on investment, making it indispensable ideal process equipment for cost-conscious printing and packaging industries. |

| Tag:book binding,book finishing,book shrink wrapping machine,heat shrinking |

Please Leave Your Messenger Here!

We will do our best to make your business prosperous!